EC-Z659

4/24

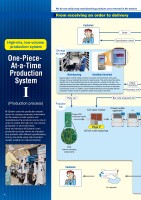

We do not easily stop manufacturing products once released in the marketFrom receiving an order to deliveryM-System uses the production master server to manage necessary information for the make-to-order system and manufactures the products one by one in order to realize the high-mix, low-volume production in short lead times.Here we introduce M-System's own production process where we manufac-ture products with different specifications one by one while using chip mounters usually suitable for mass production.CustomerCustomerAir shipmentI(Production process)Handheld terminalWarehousingApproximately 12,500 models of parts are stored and inventoried in the parts storage. We use handheld terminals for warehousing. The work instruction will be directly sent to the handheld terminal of each person in charge of the task. The staff can perform the tasks efficiently just by following the screen instruction of the handheld terminal because the instructions are sorted on the screen to eliminate unnecessary moves. In addition, each handheld terminal communicates with the production master server to update the stock in/out data in real-time.High-mix, low-volume production systemProduction lineOrderSpecification checkInventory infoParts outBar code engraved infoCO2 laser marker(2D bar code engraving)#1PCB before mounting componentsPut the PCB in the laser markerOne-Piece-At-a-Time Production SystemStorage for partsCream solder applicatorCheck inventory Page 74

元のページ